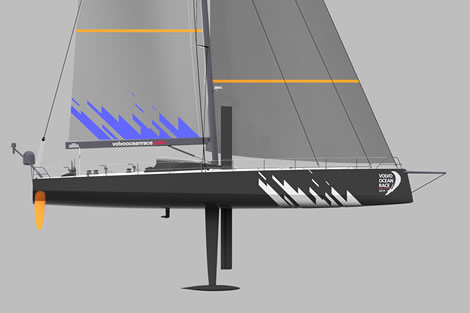

Introducing the Volvo 65 one design

The worst kept secret in yachting was finally unveiled on Thursday with the announcement of one of the most dramatic ever steps in the history of the Volvo Ocean Race. The 2014 fully crewed round the world race will see the Volvo Open 70 dispensed with and rather than replacing it with a multihull of some description or a more one-designed version of the VO70, instead teams will be campaigning a brand new 65ft Farr one design to be sailed by crews of 8.

The reason for this move is purely austerity, reducing costs in order to encourage more teams on to the start line next time around. While it doesn’t seem long ago it was introduced, the Volvo Open 70 has been used in the last three Volvo Ocean Races (the same number as the VO60 was used) and despite the cost limiting measures introduced for the present race, campaign budgets have still managed to stray into the 30-40 million Euro region whereas the vision of Knut Frostad is that for the next race this figure should be in the 12-15 million Euros region.

While 'people' – including salaries, hotel rooms and air fares - still represent the biggest chunk of a VOR team’s budget, the second biggest cost is the boat and its associated costs, with a top notch, fully developed VO70 getting on the water for figures these days approaching 10 million Euros (about the same price as it cost to build the 140ft long Banque Populaire maxi tri that many of the Volvo crews were gawping at in Lorient last week...)

In comparison the new VOD65 looks set to cost 4.5 million Euros in the water, ready to sail. So in addition to the reduced capital cost of the boat, with a one design in a stroke so all technical development costs for the boat either before or after launch are dispensed with. However inevitably the goal posts will move, shifting to the calibre of the sailors, absolute excellent in crew work and learning how to get the most from the one design. As Grant Dalton told us – now is a good time to be top level ocean racing navigator as their services will be at a premium.

In addition to the economies of scale in building a one design, there will also be considerable economies of scale for the shore-side of the teams entering the next race. Maintenance of the boats seems set to be carried out not by the teams but by the builders with some suppliers likely to be contracted back to service their equipment – for example the spar manufacturers, hydraulics, electronic and electrics suppliers, etc. So no longer for example will each team need its own specialists to maintain these areas and gone will be the enormous shore teams, some of which in this race have swelled to 25 in number.

“Spares are huge,” Volvo Ocean Race CEO Frostad told us. “Because at the moment they all have complete sets of customised one-offs. Take the mast manufacturer – what prices they can offer when they can build rigs which are still in high tech carbon, but simpler without custom locks and then building 12 or 14 identical - it is around 30-40% the price of building custom one-offs. Then on top of that there’s the standing rigging, the cost of that and the costs of things being close to breaking point or, worse, breaking, is significant.”

Frostad says they have been speaking to the teams about how the shore set-up could work with more shared resources, from spares and sail lofts. “The teams themselves have come up with some pretty extraordinary savings.”

There are obviously downsides going for a one design too. While all parties involved with the new boats come with huge pedigree, there will inevitably be some cock-ups given the time pressure and that construction of the moulds is set to commence next month... Obviously if there is a fault then the culprit item will have to be replaced across the fleet, as the forestay bottlescrews on Chay Blyth’s first generation British Steel Challenge yachts had to be.

Our biggest concern is that with the Volvo Ocean Race boats going one design, the only way for crews to make an impression in the race will be to push the ^%$^ off their boats and this in turn could lead to yet another carnage-strewn race, which the organisers are very keen to avoid repeating. For the VOR65s will still be pretty much state of the art race boats with high stability and as a result high performance, and yet the teams are already referring to them as ‘rental cars’, as an indication of how their crews even at this early stage are expecting to drive them. So the solutions to this would seem to be either the crews learn to respect their boats and back off (which won’t happen) or the new VOR65 is designed and engineered in a such a way that is becomes VO60-like in its ability to be pushed to the limit without destroying itself. This is also unlikely to happen.

Farr Yacht Design President Pat Shaughnessy shares his views on this: “Philosophically the boats don’t want to be and can’t be completely unbreakable. But what we do is that we predict loads and then we work with suppliers and other people in the process to agree on what those loads are and what factors you apply to them in the design process and it is a shared experience.

“I want to say early on that no one wants the boats to break less than we do. At the same time I don’t think the sailors want boats that are completely unbreakable and I am not sure it is necessarily achievable because you will always see an environment where the boats get pushed so hard that there will be failures somewhere and if the boats don’t break, then the people will...”

Shaughnessy says they are also investigating a third option involving more prolific use of fuses. ‘Hard’ fuses we have seen used widely in endurance events like the Vendee Globe, where for example lashings of line of a known breaking strength are put ‘in line’ with key loaded areas such as the tack of a headsail. If the fuse ‘blows’ then there is a secondary device such as a more beefy strop there to prevent catastrophe. However Shaughnessy says he is more thinking of hydraulics: “Using hydraulics on deck systems you are able to have a relief setting on a cylinder that is a natural way of relieving a load and a process without blowing up a fuse or breaking a piece of structure. With an actual hard fuse [like a lashing] if that breaks, then what happens? Someone gets hurt or the damage resulting from the fuse blowing causes some trickle on effect. A soft fuse like a hydraulic cylinder in the system is a good way to resolve that.”

So the new VOD65s are lining up to be fully kitted out with hydraulics – in addition to the ram for the canting keel, each forestay will be fitted with a ram to pull the tack down once a sail is on its masthead lock, plus the normal array for the mainsail controls.

We can’t help feeling that someone somewhere can come up with a better solution than this.

Getting faster

Matters may not have been helped by how the VOD has evolved. It was initially a 68 footer, then 65ft then 62 and is now back to 65ft, but importantly input from the sailors has given it more of a performance edge. So righting moment has increased and with it the loads and more potential for breakage...

An interesting part of the VOD65 conception process for Farr Yacht Design was investigating the bang for buck of various performance enhancing features.

The VOD65 for example has a righting moment of 33 tonne metres, compared to a fully ballasted VO70 which comes in at close to 40. It would have been possible to come up with a VOD65 capable of having the same righting moment as a VO70 by for example adding more water ballast, but this was discounted for reasons of cost and complexity as well as having to scale up the rest of the gear on board to accept the higher loads.

However the water ballast arrangement on the VOD65 is more complex than the 70 with two stern tanks located in the aft corners rather than a single one on the centre line and the new addition of a forward water ballast tank. The latter is there, says Pat Shaughnessy, to replace some of the ability to trim the boat fore and aft due to the VOD65's stack being reduced in size with less sails being carried. In addition pumping on board water up forward is also useful in increasing displacement and helping the boat power through waves in sloppy upwind conditions.

So increasing draft from the VO70’s 4.5m to 4.7m on the new one design combined with removing some weight from the bulb was found to be one of the most cost effective ways of increasing righting moment and performance. 4.7m is no small draft and Knut Frostad says they obviously had to look closely at the ports they are considering for the next race to ensure they will have enough water. On this race the shallowest draft port was Auckland with just 5.1m.

Pat Shaughnessy (left), with Knut Frostad and Multiplast's Yann Penfornis.

According to Frostad they are also looking at ways of minimising the stacking for the reduced 8 man (or 10 women) crew. So an IMOCA 60-stylee stacking system? “We are looking at sealing things so that you only stack sails and how you control that because the whole of stacking of food 24/7 is not necessarily is a core value of our sport!”

On the positive side while Russell Bowler will be working his engineering magic within the Farr office, at least two other engineering consultants are likely to be brought into the project while the yards involved will be carrying out their own materials testing and sampling and there will be a major quality assurance program put into effect. In addition Volvo also has their own specialist structures expert working on the project who comes with a background both in Formula 1 and also in offshore powerboat racing. “I think on a scrutiny side there is a pretty open and thorough approach to it although there are some significant challenges to do all that in the time frame that we have,” says Shaughnessy.

Camels

With the involvement of so many parties one gets the impression that the end result could very easily be a design by committee or “a camel,” as Pat Shaughnessy corrects us. “I don’t think we are in danger of that at the moment. Certainly there are people who aren’t getting what they want. But that happens in any project.”

Certainly input from the sailors has resulted in a more high performance machine than Farr were initially offering. On the shopping list of go faster features one option Farr suggest was to reduce the cost of having twin daggerboards with a single centreline gybing daggerboard of the type fitted on PRB for the 2000 and 2004 Vendee Globes. However this didn’t find favour. “You still have to sell them to your client and ultimately we need the sailors to like the product and be excited about it and promote it because they go to the sponsors and get the money and they say the exciting things in the media about it,” says Shaughnessy.

In part two of this article we look at some of the detail of the VOD65 design

Latest Comments

James Boyd 03/07/2012 - 11:08

A good point certainly but I think for the next race the engineering of the boat and integrity of the one design will be more important than the raw design itself. Historically Farr has been top dog when it comes to one designsMikko Brummer w... 03/07/2012 - 09:31

Good question, how could Juan K be overlooked? No mention about the sails, will they be North monopoly? There would certainly be no need for that, not on cost pretext anyway.GBR7154T 02/07/2012 - 15:54

I'm intrigued as to why the design is to be from Farr Yacht Design rather than Juan Kouyoumdjian's Juan Yacht Design. Given the track record of the Juan K Volvo 70s, you'd think that might be the obvious choice?Add a comment - Members log in