Spanish Vendee Globe line honours contender

With a strong participation in the Barcelona World Race, so Spain looks set to be fielding a potentially line honours-winning entry in the Vendee Globe for the first time.

In the past just one Spanish sailor has completed the quadrennial singlehanded non-stop lap of the planet – the legendary solo sailor and former BOC Challenge competitor, Jose Ugarte back in 1992. In the 2000 race, superyacht skipper Javier ‘Bubi’ Sanso took part, but was forced to pull out with rudder damage. This time though Sanso, currently Spain’s most capped IMOCA 60 skipper (his CV also includes the first Barcelona World Race and three Transat Jacques Vabres on 60s), is back not just to deal with this unfinished business, but with a brand new state of the art boat in the form of Acciona, an Owen Clarke design (in conjunction with Clay Oliver) built by Southern Ocean Marine in New Zealand.

In the past just one Spanish sailor has completed the quadrennial singlehanded non-stop lap of the planet – the legendary solo sailor and former BOC Challenge competitor, Jose Ugarte back in 1992. In the 2000 race, superyacht skipper Javier ‘Bubi’ Sanso took part, but was forced to pull out with rudder damage. This time though Sanso, currently Spain’s most capped IMOCA 60 skipper (his CV also includes the first Barcelona World Race and three Transat Jacques Vabres on 60s), is back not just to deal with this unfinished business, but with a brand new state of the art boat in the form of Acciona, an Owen Clarke design (in conjunction with Clay Oliver) built by Southern Ocean Marine in New Zealand.

Sanso’s sponsor Acciona is a giant Spanish company with 34,000 employees around the world and a diverse portfolio of businesses from building roads in South America to desalination plants in Australia to hospitals in Canada to a ferry company that operates between the south of Spain, the Canary Islands, the Balearics and Morocco.

However, like Mike Golding’s sponsor Gamesa (another Spanish company), Acciona is also a serious global player in the renewable energy market. Hence why one of the principle features of the new IMOCA 60 is that she is fully ‘eco’, relying on solar, wind and water power to drive her electronics and hydraulics and carrying no fossil fuels. The only fuel - apart from wind, sun and water - is some hydrogren to run her fuel cell that in turn powers her electric engine – and these are only on board in order to fulfil IMOCA class rules. Typically Acciona will be powered by her enormous array of solar panels.

This is the only new generation design from British designers Owen Clarke for this year’s Vendee Globe, their last being Mike Golding’s Ecover 3, since rechristened Gamesa.

According to designer Merf Owen (who will be expanding on the design side of the Acciona 60’s creation in a separate article), in their work on Ecover 3/Gamesa prior to the last Vendee Globe they added more reaching potential at the cost of upwind performance and they have since moved even further in this direction with Acciona. So compared to Gamesa, the new boat has a more powerful hull shape, with a little more beam. She still has a fine bow but with more volume forwards, with huge chines that run from bow to stern. Significantly while Gamesa is fitted with a powerboat-style interceptor on her transom, this has since been prohibited by IMOCA class rules, however Owen says there is still enough rocker at the stern enabling the boat to be pushed hard downwind, sans interceptor.

Skipper Javier Sanso gave his impressions of sailing his new boat: “It doesn’t bury the bow. We have done some top speeds and the moment you think ‘wow, we’re going down’, it pops up. I have never sailed on a boat that doesn’t bury its bow at high speeds like this one. I can’t wait to test it against the other boats.”

Another obvious development is the trench running mid-ships down the length of her foredeck. A nice foredeck paddling pool for the kids, you might think, but in fact the sides of the trench are the equivalent of running two stringers down the length of the foredeck. Thus it makes the deck extremely stiff, enabling its panel weight to be reduced, lowers the deck’s centre of gravity and requires there to be less reinforcement inside the boat. And in case you’re wondering what happens to the water that accumulates in the trench, there is pipework that runs below to drain it.

Acciona obviously has a canting keel, but the twin asymmetric daggerboards that accompany this are straight (unlike the curved boards on some of the VPLP-Verdier designs), are toed out and are ‘conventionally’ positioned (unlike the heavily toed in boards on MACIF and Banque Populaire) just forward of the mast, their exit through the deck halfway between the mast and deck edge. Merf Owen says they carried a huge amount of R&D into the boards, comparing all the different sorts – but more on this later.

As on Gamesa, the twin spade rudders are conventionally mounted under the transom and are unique among the new generation 60s in not being kick-up, relying on the heel of the boat to lift out the weather rudder. While this may prove to be a issue in the event of a collision with flotsam, there are plenty of tales that have done the rounds of the 60 fleet of kick-up rudders accidentally kicking up causing all manner of chaos. Having fixed rudders is certainly a lighter solution.

The rig again appears to be fairly conventional but in fact is ‘keel stepped’, which in modern parlance means it is fitted to a girder on top of the hull, elevating the mast step. The carbon spars are from Lorimar in France and Owen is particularly pleased with how they managed to reduce the height of the spreaders. This lowers VCG as does having the mast step lower, along with the structure it sits on and the jack points for the rig. “And it obviously means we can tune the mast bend nicely as well,” adds Owen. The mast appears to be well aft in the boat and Sanso confirmed to us it is a metre further back than it is on Gamesa. As a result their boom is 1m shorter but this allows her headsails to be bigger.

IMOCA 60s are now limited to 10 sails and on Acciona these have come from Christophe Cudennec at the Incidences loft in Brest, France. Sanso says there are three slots they are still playing around with, as they try to establish the best sort of spinnakers and reaching sails for using singlehanded.

The standing rigging is Future Fibre’s new carbon fibre TDS. Sanso says they were considering making it continuous but in the end opted against this for reasons of safety “even if there is a little more drag”. There are top mast backstays but these are each fitted with a deflector for when the fractional headsails and kites are used.

Forward, the stay for the solent jib is permanently fixed (as required by class rules) while aft there is a removable staysail, and forward additional points on the bow and on the bowsprit to hoist the bigger gear – a fairly typical IMOCA 60 set-up.

The aft half of the cockpit area is taken up by a large articulating solar panel (not shown in the photos), so the working area of the cockpit is forward, continuing the trend we are seeing in IMOCA 60 design at present, back towards smaller, safer cockpits that shorthanded crews are less likely to fall out of. The solar panel area is divided off from the working area of the cockpit forward by the slightly dished main sheet track and the beam supporting it. On this are mounted two winches for the mainsheet and traveller.

Protruding through the main sheet track beam are twin tillers, curved carbon fibre custom-built affairs with an extension that pulls out from their centre allowing Sanso to helm sheltered from the elements within the doghouse.

The cockpit is fitted with a primary each side and an extra pit winch to port with a single coffee grinder that can drive any of the winches. The winches are from Harken and fitted with load sensors.

While there is space for seating between the primary winch and the bank of jammers on the starboard side, to port Sanso will have to negotiate the pit winch when he wants to steer from within the doghouse (which he seems quite ready to do). But mostly Sanso will steer from either side of the cockpit just aft of the cabin top (where there are controls for the pilot and keel hydraulics), although for most of the Vendee Globe the autopilot will be in charge. As he puts it: “You can sit under the cover on the port side. It isn’t as comfortable, but I tend not to drive so much...”

The cabin top/doghouse is an angular almost Batmobile affair (except in red), similar to the new one fitted to Gamesa last year. There is a forward-facing window, but on Acciona this looks into the cabin and then through another window on the front of the cabintop, which Sanso says works okay for him. The doghouse has a fixed top, with no sliding extensions - as found on other new 60s and there is also less headroom beneath it compared to the equivalent on Gamesa (although a lower cabintop equals less windage).

Like Gamesa there is a hatch protecting the companion way that has its hinges at the top, so it flips up out of the way, held to the underside of the doghouse by a magnet. The hatch is smaller than the one on Gamesa.

Down below

In the ‘saloon’ area, unlike on Gamesa, there is really no furniture at all - no bench seat and no dedicated chart table. Sanso explains that the number one priority was performance, pure and simple: “I have no demands on habitability. I am not complaining. I know Mike’s boat is very comfy, but I don’t care. There’s no headroom, etc.”

Sanso says that when racing he will use a bean bag to sit on. The lack of headroom comes thanks to the cabin sole being elevated by the two substantial water ballast tanks and compartments for the electric engine, the batteries and the canting keel.

The water ballast configuration on board is unusual in that there is no forward tank - for reasons that Merf Owen will explain tomorrow. In addition to the two tanks in the main accommodation there is another around the keel box and two more aft.

The canting keel has a stainless steel fabricated foil that is angled slightly forward. Unusual among recent IMOCA 60s is that the keel is canted via twin hydraulic rams – made in titanium. According for Sanso he chose to go for two rams rather than one for safety reasons. The hydraulics on board were developed in the UK by Bob Jackson of Target Fluid Services.

An area of development though is the attachment point for the keel which on Acciona is entirely built in carbon fibre. We weren’t allowed to see this, but Sanso outlines it: “The pieces that hold the keel are structurally very highly engineered. You normally have some plates, that hold the keel and you bolt these pieces to the bulkheads. These pieces on the keel are normally metal which bolt through, but this it is all in carbon. The bearings sit on the carbon structure and it is actually one huge piece of monolithic carbon.”

According to Merf Owen the structure down below is very different to what they have done previously. This is partly due to the mast no longer being deck-stepped but also thanks to the deck trench. This and other factors allowed them to get rid of one of the bulkheads. So down below there is a substantial ring frame/partial bulkhead either side of the keelbox with the mast and daggerboard cases in front of this and then a full bulkhead.

The nav area, as it is, effectively comprises the instruments and computer display mounted on the top of the bulkhead forming the aft side of the keel box.

All-eco

Certainly one of the most impressive aspects of this boat is its alternative energy non-fossil fuel set-up. Sanso complains a bit about having to take an engine at all “we’re supposed to be sailing around the world...” However the IMOCA class rules require that the engine be adequate to drive the boat for five hours at five knots and fulfil a 280daN minimum pull test on the dock for 15 minutes.

“Five hours at five knots is a question of the size of the battery bank,” Sanso explains. “The pull test is more about power and that is why we had to play with the hydrogen, because we have fuel cells of 3000 watts.”

When we saw the boat the hydrogen bottles were bulky and were temporarily fitted in the cockpit. However come Vendee time, carbon fibre ‘racing’ bottles will be fitted that are smaller, stronger and capable of withstanding more pressure and significantly they will weigh just 6kg, compared to 20. The smaller bottles will be mounted in a locker beneath the cockpit sole. And of course as a result of this there is no fuel tank below.

The engine itself, fitted immediately inside the cabin entrance, is tiny and light (around half the weight of an equivalent diesel), but above it is quiet with almost no vibration. The engine is made all the more compact since there are no alternators, hydraulic pumps and the like being hung off it. Even the transmission system is simplicity itself – with no gearbox (you go into reverse by changing the polarity of the electric motor) and just one coupling - a pulley that directly attaches to the shaft for the folding prop - thereby minimising any reduction in horsepower between engine and propellor.

Sanso says that the fuel cell is only there to comply with class rules rules and given the choice he wouldn’t have it on board. He expects not to use it during the Vendee Globe although it could come in handy as a back-up in emergencies. Acciona’s power will otherwise be derived principally from her enormous 12sqm array of solar panels (each square metre pumping out 215w). These run the length of the boat on each side, along the cutoff gunwhale outside of the lifelines, with, as mentioned, an additional articulating panel fitted aft in the cockpit, which Sanso says provides around 30% of the solar panel output.

Because solar panels don’t work at full efficiency when they are even partly obscured, the spinnaker sheets and the runners are piped into the cockpit below deck.

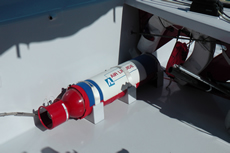

In addition, there are two Watt&Sea racing hydrogenerators fitted on the transom, one for each tack. Sanso says that these are only ever used when boat speed is more than 12 knots, and above 13 knots their drag is negligible. Originally developed by Vendee Globe skipper Yannick Bestaven, these cute devices, now popular throughout singlehanded race boat world (all the Global Ocean Race Class 40s have them for example), are built in carbon fibre and have a variable pitch propellor to regulate their output. When deployed each can deliver 450 watts at 12 knots boat speed and can be flipped out of the water when not needed.

There is also the possibility of fitting a wind generator but Sanso says it is more for back-up as they do create a lot of windage.

The solar panels are very special - custom-built in Germany by a specialist who more normally provides his product to go on satellite or for projects such as the Solar Impulse solar-powered airplane. Sanso points out that these panels are the highest efficient panels you can get with silicone cells – working at 22% efficiency and weighing less than 2kg per square metre.

While the main event for Acciona will be the Vendee Globe, her first official event will be the IMOCA class’ Europa Race, starting from Istanbul on 5 May.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in