Swiss C-Class favourites

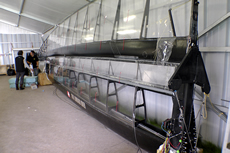

While Canadian Fred Eaton has won the last two International C-Class Catamaran Championships, favourite going into next week’s event in Falmouth is the Hydros Lombard Odier team from Switzerland.

Led by Jérémie Lagarrigue, this is the same group that created Hydroptere.ch, the foil-assisted catamaran we sailed last year, that has since gone on to break several records on Lake Geneva.

Ten people have been working full time for two years on the two-boat Hydros C-Class campaign, but over this period some 56 people have been involved in total.

Among its sailors, the team features some of the world’s top dinghy catamaran specialists including Billy Besson - this year both the F18 and the Nacra 17 World Champion - who helms for Lagarrigue, while Dutch F18 gurus, Mischa Heemskerk (also the A-Class World Champion) and Bastiaan Tentij, sail the other Hydros Lombard Odier C-Class.

The Swiss C-Class campaign has been underway for around two years now and whereas the other two boats teams here in Mylor comprise boats of different generations, the two Hydros Lombard Odier catamarans are near identical – the only difference is their rudders: on Besson/Lagarrigue’s boat they are transom hung, on the other boat they are spades.

The Hydros platforms and wings have been designed by VPLP. However the foils were developed in house, starting with base data the team gained from hydroptere.ch.

Foiling was one of the key developments of the Swiss C-Cats and, like Groupama with their foiling F18, the team spent much time developing this on board their flying Nacra 20 – including working on optimum foil shapes and movement (cant and rake, etc) as well as how to use all these in different conditions and through manoeuvres.

Developing the foils on the Nacra 20 was far easier, says Lagarrigue, because they could throw the boats around with relative impunity (something they can’t do with the Cs because of the constant fear of capsize, and resultant destruction of the fragile costly wing).

According to Lagarrigue they had originally planned to build one foiler and one non-foiler C-Class, but this changed early on with their Nacra 20 testing: the first time they went out on foils they hit 29 knots, while their top speed over their trials was 32... They found the foiler was some 10 knots faster downwind than the low-rider, so it wasn’t an overly tough decision that both their new Cs would be airborne.

The boats and wings were built by Decision SA, also responsible for all the Alinghi America’s Cup boats, Pierre Fehlmann’s Whitbread maxis, the D35 catamaran fleet, Bernard Stamm’s latest IMOCA 60, etc, etc, although the Hydros Cs were subsequently completed by the team. Engineering work was carried out by Herve Devaux Systems (HDS), who also worked on the second Artemis AC72.

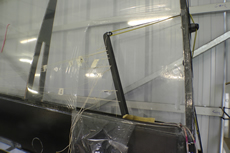

Significantly, the two new Hydros catamarans are the first race boats to be built using North’s ‘thin ply technology’ (TPT), the same technology that goes into Southern Spars masts and North 3Di sails.

The laminate of the hulls for example comprises three layers of TPT (roughly the thickness of a sheet of paper) either side of 5mm Nomex. The hulls were female moulded and such was the quality of the build that the exterior of the boat has no filler and is unpainted.

According to Lagarrigue, the only issue with boatbuilding using TPT is that it is relatively doesn’t like going round corners. Just getting used to using it added a month and half to the build. “The process is the same, the only thing is the temperature, and the process of cutting the TPT to be able to apply it on a form like this. TPT is easy to apply on flat surfaces, but as soon as you have one or two curves, it is hard because it is brittle. But it allows us to use three times less carbon than normal.”

The Hydros boats have wave piercing bows (similar to the design of Lionel Lemonchois’ new Prince de Bretagne tri) while their hulls have moderate rocker to improve their turning ability. Unlike most of the other Cs, they have straight tubal crossbeams and, significantly, the decks rise up to attach to them, in order to help keep the beams out of the water. Lagarrigue says that the boats were designed for an end of September regatta in Falmouth and so they were concerned about the sea state, expecting 0.7-1.0m high waves. Thanks to using TPT, adding freeboard to the hulls at the cross beam joins came out at roughly the same weight as if they had built curved cross beams.

Weights are a reasonably closely guarded secret in the C-Class. Lagarrigue won’t divulge the weight of the boards, but the platform ready to sail he says is 60kg, the individual hulls are 20-28kg (depending on what you include), the weight of the wing is around 60kg or 69kg with everything on it, while the all-up weight of the Hydros C-Class cats, ready to sail, but without the boards, is a feather weight 150kg. Perhaps most impressive of these figures that the difference in weight between the two wings - just 20g...

Foiling

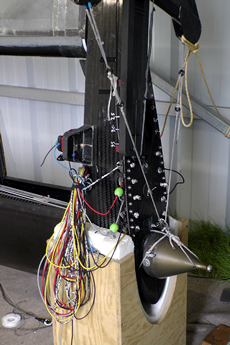

The foiling decisions on the latest generation C-Class catamarans have been reasonably similar to those made for the AC72s and it seems like the Swiss team has carried out some intense development in this area (there is a double reason for this: Hydros is set up with a commercial element – R&D gleaned in the development of their boat is subsequently sold to industry, such as manufacturers of wind turbines). So for example they appear to have tried and tested almost every conceivable way of building L-foils with different materials and cores even trying the new internal bag aerospace technique that the Sodebo team used to build its daggerboards.

The foils Hydros have on for this regatta look like a hybrid between the Oracle Team USA and Emirates Team New Zealand daggerboards – the vertical part has similar curvature to the latest Kiwi boards, but the near 90° angle between the main shaft of the foil and the tip, is more like the Oracle boards. On Hydros they can control both the cant (lateral inclination) of the boards, as well as their rake (affecting the pitch of tip). Cleverly their foils can also be inverted in the event of having to sail in conditions too light to foil.

According to Lagarrigue the end result (like Oracle’s AC72) is a boat that isn’t overly stable in flight, but is faster with less drag, the downside being that the crew has to spend more time actively trimming the daggerboard rake to compensate for the boat’s slight dolphining/porpoising motion. Because the rake adjustment is regularly used, it is set-up so that the leeward board can be controlled from the high side. The cant of the boards can be changed actively, but this isn’t done as much - mostly tuned according to the wind speed and sea state, it determines the wind speed at which the boat will lift off (usually around 6-7 knots). Typically in higher wind speeds, the amount of cant is reduced.

Lagarrigue adds foiling a smaller boat, like a 25ft long C-Class cat, is harder than it is for an AC72 which has much more momentum and is thus easier fly in a more stable manner.

To stabilise the flight, the rudders have T-foils and despite the differing set-ups on the two Swiss Cs, the rudder rake can be changed on both. Unlike the AC72s where class rules prohibit it, rudder rake can be changed during races, so for example some pitch is added to the rudder foil to enable stable flight when sailing upwind.

Unlike the AC72s, the C-Class cats aren’t yet able to perform foiling gybes, although Lagarrigue says they are close. He explains: “It is difficult, because you need to maintain speed and you go faster than the wind to make the wind pass in front of you, but as soon as we come in from the trapeze we lose 8 knots and, when we gybe, we don’t have enough speed for that to happen, so the foil stalls, the boat drops down, and ‘bamm’ we just touch and then we restart.”

Lagarrigue says that their abilitiy to foil upwind came as a surprise. They tried it once in a casual test. While low-riding they were regularly sailing at 13 knots upwind, but foiling they can make 17-19 knots in around 14 knots of wind. And this was at no flabby angle - typically they would bear away by around to 50° TWA to help take-off, but once up and foiling they would head up to around 45°.

Upwind, Lagarrigue says they haven’t done anything to address leeway other than that the vertical area of the foil is enough to counter the side force of the wing, provided that the majority of the foil is kept in the water. He adds that it would be possible to rotate the foils slightly to provide lift to weather, but instead they have fitted asymmetric foils that achieve much the same effect.

Wings

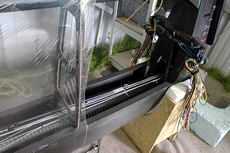

The Hydros wings are beautiful, also designed by VPLP. The way to spot a modern C-Class wing is the amount of curvature it has – building like this has become a lot easier, possible even, with the ever increased use of CNC-milled tooling.

On the Hydros wings, EVERYTHING is curved – the front elements, the flaps, plus the leading and trailing edges of the rear element.

A design aspect they also considered was the stability of the wind up the height of the wing. For example low down there is much turbulence because of the interaction between the wind and the surface of the water, while the top the wing goes through considerable acceleration and deceleration thanks to the pitching of the boat.

Half way up, the wing is at its most stable. Thus here, the wing can have the most efficient shape with both more chord and a narrower profile, compared to the top and bottom, which have a fatter profile, providing better all-round performance – so the percentage of the overall chord is around 50-50 in the middle of the wing, 40-60 at the bottom and 45-55 . This also affects the size of the flap between the front and rear elements up and down the rig says Lagarrigue.

While the components of the Hydros wing are familiar, their relative proportions aren’t.

The team made a lot of studies into the design of the wing and according to Lagarrigue, one of the keys is the rotation point of the flap, hung off the trailing edge of the front element, relative to the rear element. On the Swiss wings this flap is larger than it is on other C-Class wings, which is vital for achieving a high lift to drag ratio and maximum efficiency at full camber. Divided by the hinges linking the front and rear elements, the flap is in four sections, although they are operated by one control line.

Like the majority of C-Class wings since Cogito in the mid-1990s, twist can been induced up the front element (as well as up the rear element). However whereas on Cogito and the majority of the C-Class built since, this front element twist extends up to the hounds, on the Hydros wing it extends about 7/8ths of the way up the wing, with the front element divided into two sections. 10° of twist can be induced in the top part of the front element, 15° in the bottom.

Because of this they have one more line to control the twist in the top of the front element, compared to ‘conventional’ C-Class wings in addition to the overall sheet and camber controls, twist in the rear element and twist in the lower part of the front element. There is additional control that helps the wing tack, but only in very light winds (ie less than 5 knots). “In 3 knots you want maximum twist to attach the flow, otherwise you can’t go deeper than 110,” says Lagarrigue. “If there is not enough wind the element doesn’t twist and so we have to force it, and pull the rotation of the leading edge.” The line is called a ‘forcetter’ in French and we’re still waiting to find out the proper English translation.

Aside from having two of the most state of the art C-Class catamarans, the Hydros team has also benefitted from spending the most time on the water. They have spent the longest in Mylor, having set up shop here around one month ago. They were testing their Nacra 20 in La Grand Motte in the south of France from February and there with their new C-Class cats from the end of May.

The upshot is a pair of the absolute state of the art in the C-Class fleet with some amazing performance numbers – in 7 knots they can hit 24 knots (or 3.5x wind speed), or 30 knots in 10 knots. None too shabby for a 25 footer.

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

||

|

|

Latest Comments

wizdeas 24/09/2013 - 20:01

Great article. ThanksAdd a comment - Members log in