Under the skin of the new Azzurra TP52

The only new TP52 on the ’52 Super Series’ is the latest Audi Azzurra Sailing Team, the joint Argentinean/Italian effort backed by Matador’s Alberto Roemmers representing the Yacht Club Costa Smeralda.

This is the Azzurra/Matador team’s fourth new TP with three Judel-Vrolijk designs previously in 2007, 2009 and 2011, the last being one of the two ‘fat’ boats, along with the Franco-German Audi Sailing Team powered by ALL4One. The latest boat however is a Botin and Partners design, a development of last year’s season winner Quantum Racing and built, like Quantum, by King Marine near Valencia.

“The boat was a Volvo 52!” says Simon Fry, eminent sailmaker and downwind trimmer, last year’s Azzurra. “It was possibly a little radical. At times it was blisteringly fast, but at times it really struggled. It was quite a difficult boat to sail. The powers that be decided that we would run a Botin this year and here we are.”

The new Azzurra’s hull shape according to Fry is very very similar to Quantum Racing (and sistership Synergy, which sadly isn’t racing this year), with a slight chine, although the rudder is a fraction further aft compared to the 2011 boats. There are obvious differences between the Vrolijk and Botin designs particularly under the water where the former’s keel is in a T-configuration, whereas the latter has more of an L-shape.

In terms of how the new boat behaves on the race course, Fry says it is markedly different. Generally it is much easier to sail, less quirky and more forgiving to heel. “Obviously you try and sail on your heel targets, but if you want the boat to go faster you press on it, you don’t have to do a radical trim changes. Upwind it has done everything we wanted it to do. Downwind we are still learning because it has some quirks and foibles we are still finding out about.”

Most noticeable is the deck arrangement. TP52s have to comply with a minimum coachroof height under their class rules. So the Vrolijk boats have a distinct coachroof (which allows a lower centre of gravity), while the Botin boats have their coachroof virtually hidden within a more heavily cambered deck around this area that helps reduce windage.

Since the 2010 and 2011 seasons when the TP52s went through two developments with their rule, adding bowsprits, twin backstays and flat top mains, and removing most of the huge amount of corrector weights in their hull, etc so wholescale developments are now few and far between but work continues to move apace for each team’s in-house technicians.

The aim generally in the TP52 class remains to try to reduce weight overall and lower the centre of gravity and also to minimise windage on deck. Thus on the new Azzurra, the cockpit sole is covered in stripes of grip tape rather than being fully non-skid, thereby saving half the weight... I kid you not.

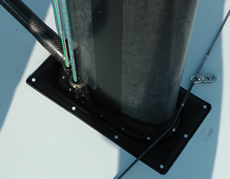

The whole boat looks very clean aerodynamically. This is particularly noticeable around the mast and foredeck area where the jib halyard (the only external halyard – allowing the jib to be bounced up) fits into a recess on the starboard side of the instrument display mount.

The gooseneck is protected by a sleeve of neoprene, that also reduces potential for chafe. “That is something your average guy in the Solent can do - you will never rip the chute on the gooseneck again, it is very smooth,” says Fry.

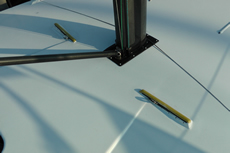

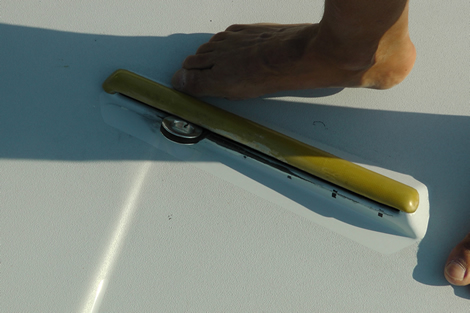

But cutest of all are the jib tracks which run below decks (as they had on Quantum last year), the ring protruding through a narrow aft-facing slot in the deck. “You get to seal the jib to the deck with the best end plate you can have - the clew is in the block,” says Fry. But it allows water in? “A little bit... You wouldn’t say TP52s are water tight...”

Still a significant area of development as usual on TP52s is the pit area. While there was once a trend for using a driven pit winch for hoists, last season none of the boats had a driven pit winch and in the most radical case, Container, had no pit winch at all. So on Azzurra the pit winch is merely a snubber and for hoists the halyard led aft to the spare primary, while the primaries have a rotating base so that on gybe sets they can cross sheet.

All the boats use spinnaker take-down systems and Fry says that there have been advances with these over the last 18 months, in particular where the drop lines attach to each chute. Then there is the drop itself. As he describes it: "It’s a case of being more aggressive, smoking the halyard and, on a windward drop smoking the tackline. Funnily enough the Melges 32 has helped a lot. That is a small boat and it behaves like a small boat, so you smoke the tack line and it all goes up in the air and then you pull the chute down and it is all manually powered. Then you think ‘why not do that on the 52?’ And it works. To be fair New Zealand used to unload the tack in 2007 in Valencia. I think they were the leaders of that – any drop they did they would smoke the tack line to get it up out of the water and then ready for retrieval.”

To further minimise the mechanics within their pedestal system, only the port main sheet winch is now driven, instead the drive shaft heading starboard from the X-box, now drives the 400mm carbon fibre spool for the spinnaker drop line.

The bow area is pretty standard with a trough for the jib tack. However on Azzurra the forestay is fitted with a cunning device which Fry personally lays claim to developing. On TP52s the rake of the rig can be adjusted, limited by a maximum throw of the ram below deck of 255mm. This is a significant amount of rake, so to prevent loss of J-measurement when the rig is raked aft so there is a Spectra strop loops around the bottom of forestay, known as a ‘triangulator’, how much the tack deflects aft/to leeward. “You can only fit it when you know exactly what the geometry is on the jibs," says Fry.

The mast on the new Azzurra is a Southern Spars TPT masterpiece. Read more about TPT here. This technology, originally behind North’s 3Di sails, allows genuinely multi-axial construction of composite parts. This gets the Fry seal of approval: “Because of the TP52 rule changes you can’t run ultra-high modulus carbon [in TP52 spars] so you have to run standard modulus. So we’ve gone for a TPT mast, so all the fibre orientation is as good as it can be. The rig is very impressive. It is even a step on from the ultra-high modulus rigs of 2009.”

Rán also has a TPT mast, as does Tony Langley’s Gladiator after they broke their mast over the winter.

A new development with the Azzurra rig is that the mast ‘floats’ at deck level allowing it a few millimetres of lateral movement in this area. Fry explains the reason why they should want this: “If you imagine you are sailing upwind and the mainsail is too deep if you sag the rig to leeward you suck out luff curve then you can sheet hard because the sail is flatter. It also rotates the sail plan up to weather, which creates helm, because in the light you are always looking for bite. That is common in Etchells and Dragons – it is a keelboat trick...”

However this is not overly easy to achieve and for example it requires a slightly larger aperture in the deck and for the mast foot to be slightly dished.

The main and jibs are on Southern Spars locks, although for coastal races (the one and only this season being this week at the Audi Sardinia Cup) they also fit one for the A3. The jib locks are external and articulate on the headstay, although the trip line runs internally down the mast.

Another neat feature is how the teams are using their jibs. Fry explains that downwind they no longer drop the jib when it is over 18 knots. So they have a special reaching jib sheet set up on a line running athwartships in front of the mast. The control lines for this exits in the back of the cockpit. “All of gybing of the jib when sailing downwind is done from back of the boat, so the guys don’t have to come forward,” Fry explains.

Overall the North sail wardrobe on board has moved almost entirely to 3Di with only the superlight jib and the light main now made in a high grade carbon 3DL. Otherwise Fry says “sail designers have spent a lot of time working on a lot of time working on the structure of skins and everyone across the group are making them lighter and smoother skins.”

Elsewhere in the cockpit there are two pedestals, the aft one mounted right next to the rudder stock. This forms part of the package from Harken, that also features the Lou Varney-developed Harken Pro-Trim. The boat has a sheet retrieval system for the kite sheets that comes from a company in Portugal and was also fitted to last year’s Azzurra and to Bribon. This is a more basic version of Varney’s ‘The Reeler’ with no clutch, and using bungee to take up slack in the line used to fire in the halyard. However it has been tweaked by Azzura’s technical team. Typically they will wind the kite sheet on to this before the start of a race, and Fry says he is thinking of fitted a dished batten which the sheet will have to run over before it reaches the bobbin to encourage the sheet to wind in neatly. All very Singer sewing machine.

Controls for the jib up and down and for the jib Cunningham/tack are located on the aft side of the forward pedestal. A tiny, but neat feature is the Harken cleat fitted on the latter which features two plastic pieces, epoxied on to the top of the cleat that allows the line to run out without it jamming. “It is a standard Harken fitting, which you find on a lot of production boats, but there is no way of leaving it uncleated, because the line will always go back in the cleat. So with this it will stay uncleated and run out,” says Fry.

Down below we weren’t allowed to take pictures. A fundamental development from the 2011 generation Botin designs is that the new Azzurra has a stainless keel floor, rather than a keel tower. According to Fry “it is a balance of where you want the weight versus structure in the boat.”

Below, as usual, it is a cat’s cradle of rope leading in every direction. The reason for this is keeping ropes below decks reduces windage as well as on deck clutter. It also means that there can be a prolific use of purchase systems so now the only hydraulics on board controls the ram for the forestay. Another development they have made on Azzurra is that all the lines running aft do so along the floor on the centreline – this not only keeps weight low down but reduces the number of 90° turns.

So as usual with the TP52 class there is nothing earthshattering to report, just 101 small things that could a few crucial metres/leg that might prove the difference between winning and losing.

From James Boyd/www.thedailysail.com

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Wacka Elvis 18/06/2012 - 14:05

very neat but got to question the ratio of money spent to podium places gained / kept... we all know what happens when this gets out of whack... the owner packs it in.geert kuypers 14/06/2012 - 09:25

Quantum was built at Longitud 0 in Burriana and not by King Marine as mentioned aboveAdd a comment - Members log in