The latest Juan K Open 60

Open 60 skipper Bernard Stamm returns next year for his fourth crack at the Vendee Globe. While the supremely cool Swiss sailor has two victories in the Velux 5 Oceans under his belt, any sort of result in the non-stop singlehanded round the world race has so far eluded him.

His first attempt in the 2000-1 race, aboard the Pierre Rolland-designed Armor-Lux, which he had painstakingly built himself, was a little premature and Stamm pulled out just nine days in with steering problems. On a positive note, his retirement enabled him to head to New York from where we ended up setting a new fully crewed west to east monohull transatlantic record time of 8 days 20 hours and 56 minutes, beating the previous record set by the ketch Mari Cha III, a boat more than twice as big.

Stamm's chances for the 2004-5 Vendee Globe were scuppered, a few months prior to the start when his yacht’s keel broke off near Newfoundland while competing in the Transat (OSTAR) and he was unable to repair the boat in time. In 2008-9, equipped with a new boat - Jean-Pierre Dick’s first Virbac-Paprec - Stamm was in the hunt, but on attempting to put into the Kerguelens to fix some rudder problems the boat ran aground and was irreparably damaged.

So could it be fourth time lucky for Stamm in the Vendee Globe? Certainly on paper he is looking formidable. After a self-build and then a second hand boat, his third IMOCA 60 is some weapon in the form of a brand new Cheminees Poujoulat, designed by Juan Kouyoumdjian and built in Switzerland by Decision SA. Aside from having been responsible for several of Pierre Fehlmann’s Whitbread maxis, Decision also built all of Alinghi’s America’s Cup boats, including their giant catamaran Alinghi 5.

Significantly on this occasion Stamm hasn’t had a constant fight to secure funding. The boat is owned by the Sandoz Family Foundation, from whom Stamm rents it. This arrangement is considerably less stressful on him. “It is okay to own the boat when everything is okay. But when you finish on the Kerguelen rocks it is a different story...”

As to his choice of designer, Stamm says he met Juan Kouyoumdjian at an IMOCA class meeting and was impressed by his motivation and subsequently the exchange they had during the design. Conception of the new Cheminees Poujoulat, he points out, was very much a two way process and wasn’t a case of “building the killing machine and then getting someone to drive it.”

Kouyoumdjian’s first attempt at an IMOCA 60, Pindar, initially built for Mike Sanderson to skipper, was designed more for the Atlantic, although she was manhandled around the world singlehanded by Brian Thompson in the last Vendee Globe and has since been modified as Alex Thomson’s latest Hugo Boss. However the new Cheminees Poujoulat is substantially different, due to her primary objective being the solo non-stop round the world race and because of changes to the IMOCA class rule. While in IMOCA 60 terms the Hugo Boss/ex-Pindar boat is a colossus, with the most beam (at 6.4m), the tallest rig (at 31.65m), the most sail area and the most displacement, Stamm’s new steed is very much less extreme.

Stamm says he paid no attention to Pindar when choosing to go with Juan K. “The important thing for me was to think about my boat, to choose my own systems and all the principles of my boat. It was very important that I didn’t copy what he’d done befoe.”

One of his first thoughts in conceiving the new boat was the horsepower and the sails. “I want to be able to use the sails, not just look at them! So we started with the sails and how we use the boat, then we looked at the hydrodynamics and the power of the hull.”

Stamm says that the way he worked with Juan K was similar to how he worked with Pierre Rolland, who having designed his Mini, then went on to pen his first Open 60. The relationship between Stamm, his in-house team and Bertrand Cardis at Decision SA was similar. In fact Cardis and Stamm are very old friends and used to sail against each other on Lake Geneva in their youth.

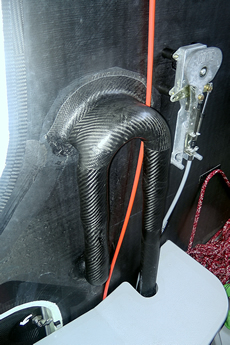

While some IMOCA 60s have in the past been built partly with a foam core or even monolithic to prevent delamination in slamming areas, techniques for building in carbon/Nomex have come on so Cheminees Poujoulat is carbon/Nomex throughout (this is also the case with VO70s).

Engineering for the new IMOCA 60 was carried out by Andrea Avaldi, in house at Juan Yacht Design, however a lot of research into the composite materials used in the build were carried out by the École Polytechnique Fédérale de Lausanne (EPFL), a long term collaborator with Alinghi on their Cup boats.

While Cardis and his company Decision cut their teeth building Whitbread maxis for Pierre Fehlmann, they haven’t built many offshore boats in recent years save for Jean-Philippe Chomette’s Open 60 Solune. “He was a little surprised by the complexity,” says Stamm of Cardis and how Decision tackled the build. “Not just the water ballast tanks, it is the fact that we plan to go full speed singlehanded - it is totally contrary to the Cup. And with that they didn’t have to manage the whole boat, they just did the composite part. Here we did the complete project together and my team was working there in Switzerland.”

While Decision built the majority of the boat, the boards and keel foil were subcontracted to Re Frascini in Italy (where Ericsson 4’s keel was manufactured), while the rudders came from Heol Composites near Vannes in Brittany.

Stamm says he has attempted to keep the boat simple, but by their nature modern IMOCA 60s are complex boats.

The hull of Cheminees Poujoulat has a chine extending all the way to the bow, like the three new Juan K-designed VO70s. But compared to Pindar her beam is a much more modest 5.8m; around 100mm more than the new VPLP-Verdier IMOCA 60s. Under the new IMOCA class rules, mast height is limited to 29m off the water, compared to 31.65m for the grandfathered Pindar/Hugo Boss, however Stamm's new boat can still fly 300sqm upwind and 600sqm downwind. Her weight remains undisclosed but is presumably much less than the deliberately heavy Pindar/Hugo Boss.

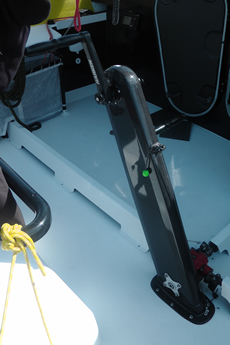

One of the biggest variations between the new generation IMOCA 60s is the location and inclination of their daggerboards, the most extreme being the Desjoyeaux-conceived Foncia/Banque Populaire which has them outboard and heavily toed in. On Cheminees Poujoulat their location is more conservative, half way between the centreline and the edge of the deck and they are slightly angled in (toed in) so that when the boat is heeled they will still provide significant vertical lift as well as preventing leeway. “It is done so you can foil a little bit, to keep the bow up and to be quite efficient when you go upwind,” says Stamm. The angle of attack of the boards can be tuned, but Stamm stays that at present it seems to be working well.

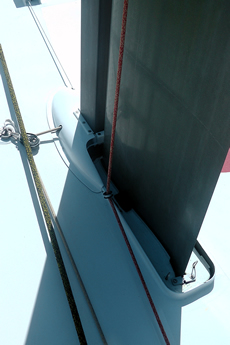

A development with Cheminees Poujoulat is that great emphasis has been placed on being able to tune the rig. The mast, a fixed three spreader affair, was constructed by Lorimar, engineered by Stamm’s own team led by Gautier Levisse and GSEA Design. Stamm says that initially he looked at fitting a wingmast as it is easier to manage when you gybe, however after they carried out a complete study on wingmast v fixed mast, the latter proved favourable, presumably from a weight standpoint and the flexibility it offered in being able to tune it.

Rather than any of the contrived systems for the vang we have seen in the past - the MichDes arrangement with the mainsheet and vang sharing a giant C-shaped track or the line running along the underside of the boom, as used to feature on past Groupe Finot designs - so the boom is attached to the mast (as has become the norm again – rather than attaching it to the deck). There is no outhaul; instead a hydraulic ram effectively does a similar job by extending the length of the boom.

Stamm points out that because the new generation boats are faster creating more apparent wind, sails tend to be sheeted more centrally, so there is less need for a giant main sheet track. However Cheminees Poujoulat’s is still full width running along the top of the transom.

On this occasion all the sails are on hooks, whereas on Stamm’s previous boat the mainsail and spinnakers were held on halyards. As seems to be popular in France, the hooks come from different manufacturers depending upon which sail they are being used for. The standing rigging is Southern Spars’ carbon fibre EC6.

Cheminees Poujoulat will carry 10 sails and a requirement of the IMOCA rules is that one forestay must be permanently fixed. Stamm says that the headsail configuration is much the same as on his previous boat except that the genoa/Code 0 is tacked to the bowsprit instead of the deck. For the sails he is working this time with North Sails France. “The principle was that we have to be able to tune the sails. We have to be able to put tension on the stays, not like before. You know it is always when you see pictures at the start there is a lot of sag. Now we have tack lines on a ram.” The keel and tack lines for the headsails are the extent of the hydraulics on board.

Stamm says they considered fitting deck spreaders with their fixed rig, but instead will have ‘outriggers’, effectively around 2m long jockey poles with two mounting points fore and aft for the different headsails.

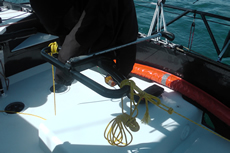

The cockpit layout is reasonably standard among IMOCA 60s. Lines run aft from the mast directly to the central pit area through a tunnel within the cabintop, while additional lines from the boards and headsail sheet tracks run aft through the sides of the cabintop. The winch package is from Harken. In the pit there is a single winch, while each side there is just one primary (a 990) and one runner winch, with a coffee grinder mid-cockpit driving the winches. The primary and runner winches on the port side wind in anti-clockwise, and Stamm admits that this has been taking him some time to get used to.

Not obvious from the photos is that beneath the coaming, where the primary and runner winches are seated, are some old fashioned cleats. These, Stamm points out, are not only simple, but light.

When we were on board there was no additional protection for the helm other than the cabintop. Stamm says that he plans to fit some sort of sliding system to offer cover over the helming position each side. The tiller in the pictures below is not the definitive item as it is too close to the grinder and will probably be replaced with a V-shaped affair. The twin rudders kick up but when Stamm discussed these the indication is that they were fitted more for their performance (less drag) rather than their safety benefits.

With the pit area located centrally, so the companionway is offset to port. The cockpit bulkhead feels that it is further aft than on other IMOCA 60s.

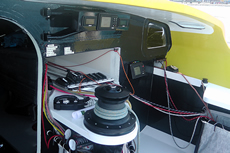

Down below is minimalist. On Stamm’s previous boat, a Farr design, there was a giant turntable allowing the nav area and galley to be hauled up to weather. On this the nav area is on a sizable pivot, enabling it to be brought up to windward. This is fitted with twin displays for the PC while the performance instruments and the all-important autopilot on board are all from B&G.

The galley, comprising a tiny sink and singleburner stove, is simply stuck with strong Velcro to the front of the cockpit bulkhead. It can be moved in its entirety from side to side between tacks.

However most innovative down below is the stacking system. This comprises a giant C-shaped track mounted on the deck head. This allows the overhead stack to be easily tacked or moved fore/aft. The stack has the potential to be shifted aft of the cockpit bulkhead. Although not fitted when we were on board, attached to the track will be a box designed to carry 500kg of gear, ie everything movable except the sails. The interior is designed so that it is relatively easy to get sails across the central water ballast tanks when stacking.

As ever on IMOCA 60s a space sapping feature of the accommodation is the water ballast tanks and on Cheminees Poujoulat this comprises two tanks aft, two centre tanks and one forward. Stamm reckons that he could bring on board around three tonnes of water in the side tanks and a further 800kg up forward, although he says he doesn’t believe he will ever use the full capacity.

In terms of fore and aft trim, Stamm says that the boat when static is slightly bow out and therefore, when sailing upwind, requires weight be moved forward to get the bow down, thereby maximising waterline length.

The keel box is immediately aft of the main bulkhead, the canting mechanism driven by one ram on the port side.

Another complication, although potentially a ground breaking development for the IMOCA 60 class, is that Cheminees Poujoulat is spattered with load cells. Dotted around her in key high load areas such as the boom, mast, daggerboards, hull, deck, keel, etc there are in excess of 100 of them.

“It was part of the principle that we have to control what we build,” says Stamm of the load monitoring system designed by Daniele Costantini, (ex-Alinghi and now with Artemis). Assuming this is calibrated correctly, this will hopefully address one of the significant issues with Vendee Globe boats, helping to remove potential gear failure (but not human error) and providing a better chance of reaching the finish line. So like recent AC multihulls, Cheminees Poujoulat will have an alarm system that will tell Stamm if he is pushing the boat too hard. “It is a prevention system, especially in the mast, where you can have a structural problem that perhaps you cannot see. It can show you that maybe you are making a mistake.”

We hope he has them attached to his keel.

While Cheminees Poujoulat competed in the Rolex Fastnet Race, finishing less than seven minutes behind the lead IMOCA 60, her first major outing will be the Transat Jacques Vabre this autumn doublehanded with one time Olympic 470 sailor, Jean François Cuzon.

Photos by James Boyd/www.thedailysail.com

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Latest Comments

Add a comment - Members log in