Acciona - design development

This article follows on from our look at Javier Sanso's new IMOCA 60 Acciona here

For Owen Clarke Design the new Acciona is their eighth and latest IMOCA 60 following 12 years involvement in the class, since their part in the design of Ellen MacArthur’s Kingfisher prior to the 2000 Vendee Globe.

Prior to commissioning the new 60, Acciona skipper Javier Sanso sailed in the Barcelona World Race aboard Mutua Madrilena (the former Ecover 2) and competed in the 2009 Transat Jacques Vabre with Mike Golding on Ecover 3 (now Gamesa) – both Owen Clarke designs.

According to Merfyn Owen they started development of a new IMOCA 60 design immediately after the finish of the last Vendee Globe, and had clients for a boat to enter the last Barcelona World Race. Unfortunately due the IMOCA 60 rule being in a state of flux at the time this didn’t come to pass.

According to Merfyn Owen they started development of a new IMOCA 60 design immediately after the finish of the last Vendee Globe, and had clients for a boat to enter the last Barcelona World Race. Unfortunately due the IMOCA 60 rule being in a state of flux at the time this didn’t come to pass.

“We had developed this idea of lighter decks, and putting a trench into the deck,” says Owen. “So a lot of the concepts in Acciona were developed a few years ago.”

When the button was finally pressed on Acciona, Owen Clarke pulled in former Emirates Team New Zealand designer Clay Oliver, who they have worked with often previously, to continue development work on the hull as they focussed on other areas of the boat.

A significant feature of the new design was the amount of R&D they were able to carry out, significantly more than they have had the time or resource to do in the past. This included examining the competition – taking Gamesa as the datum hull and comparing it with the new Owen Clarke 60, the latest VPLP-Verdier, Farr and Juan K IMOCA 60 designs and the last generation Puma VO70 type hull form from Botin & Carkeek. These were all adjusted to have the same righting moment while still complying with the IMOCA 60 rule - and its AVS and 10° requirements - in order that they could compare like with like. This study was not just confined to computer modelling, but involved two weeks tank testing at Southampton’s Wolfson Unit.

As Owen explains: “Generally what happens is that you get into a hull [shape], you develop that and there are lots of other things to look at, but they are basically all developed off a pretty similar hull form which you then adjust and tweak. So every boat, from Kingfisher through, has been a variation on a theme – because you just don’t have the time or the resource to really study what other people are doing in sufficient depth to divert away from a program that has already proven to be fast and safe, especially in the Southern Ocean. By boat seven and eight you’re a long way from Kingfisher or even Ecover 2 but each generation has developed from the huge knowledge base of the previous generation.”

In the Wolfson Unit tank they carried out the usual tests on the six models looking at how the hulls behaved upwind and downwind, the amount of leeway, etc. However during the first week they quickly pared their research down to the top three performers. From here they carried out further examination into on the final three, looking at different displacements and water ballast configurations also running the three remaining models through their VPP and simulating their performance on the round the world race tracking using the worldwide weather model in a program called Router.

And the winner? “Funnily enough is what you see is OCD 001 – the model Clay developed from the OCD hull – that proved to be the quickest hull,” says Owen.

Once they had decided upon the hull shape they then sent the lines off to the builders at Southern Ocean Marine in New Zealand to start work on the tooling for the carbon fibre female mould for the hull. Meanwhile they embarked on further tank testing using a one third scale model of their final design at the CEHIPAR facility in Madrid.

A significant difference between Acciona and Ecover 3/Gamesa is that since the latter was built, interceptors have been prohibited under the new IMOCA rule (read more about Gamesa’s interceptor here). Owen explains: “On Ecover 3 we could have fairly fine bows forward and we could have a little bit of rocker and that meant you could push the boat hard in the South. And then when you want to sail fast in flat or medium seas you put the interceptor down and press the bow down and you go faster. So [with Acciona] we had to come up with a solution whereby you could still push the boat in medium airs and go fast, which means having a low transom as if you had the interceptor down, but we couldn’t push the transom so far down that at high speed in the south the bow buried. So Clay played with the shape of the transom, the buttock lines, etc.”

As mentioned in our article on Acciona, the boat also has a more powerful hull shape and is more geared for reaching at the expense of upwind performance.

Owen is fairly outspoken when it comes to new developments in the IMOCA rule, some aspects of which have added dramatically to the cost of campaigns rather than reducing them. “The new rule was a cock-up. It was always going to be, in that I don’t believe it made the boats any safer and it dramatically increased the cost.” Part of the problem is that the minimum Angle of Vanishing Stability (AVS) was increased from 108 to 110° and Owen points out that that means nothing in terms of safety. “That is the difference between whether the boat gets hit by a 30ft sea or a 30.5ft sea. But what is does mean that you are automatically adding 150kg into the boat that you want to lose for any given righting moment. So we had to save 150kg before we even started to get back to where we were with Ecover 3 – and can you believe how much money you have to spend to get rid of 150kg?”

Owen has more criticism of the new rule, in particular the lack of a minimum centre of gravity height for the mast (which keeps pushing teams towards more risky solutions) and of any restrictions on the keel, such as permitted materials, which resulted in the Safran team fitting a titanium keel to their 60 last season (not that this proved to be a race winner).

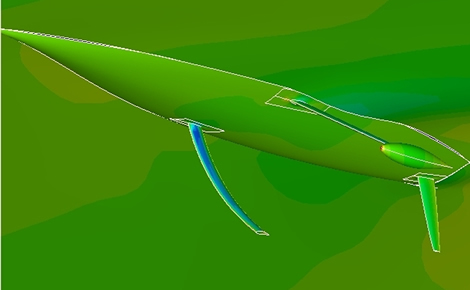

Back to Acciona and, for the foils, the team worked with Georgio Provenciali and Oracle Racing’s Mick Kermerec. Again they studied the alternatives in CFD before running the options through another tank testing session, this time using a one third scale model of their final choice of hull at the Madrid tank test facility.

“We looked at straight foils, curved foils, different angles of incidence, in the full range of boat speeds, upwind, footing, and investigated if we could possibly induce some lift in the foils reaching and the results were completely definite: The curved foil is not a player in any condition when you can sail the boat. It is fashion in hats by a large margin, that is wide enough to take into account any CFD or model testing error,” states Owen.

They also had to convince the Acciona team, which had initially believed that curved boards represented the way forwards. “Sometimes – especially if someone like MichDes does it, or a boat does well with something, then that detail can all of a sudden take on a life of its own with another project, whereas the team that chose a certain thing for their boat, may have done it for a completely different reason,” says Owen.

A classic example are the MichDes-inspired Banque Populaire and MACIF which have heavily toed in daggerboards and their exit on the deck is close to the gunwhale. Owen maintains that in this case the angle and the potential of their daggerboards to generate vertical lift is a less important factor than where the foil exits the hull and what is going on on deck, particularly with the sheeting position of the headsails. The Banque Populaire/MACIF set up allows headsails to be sheeted comfortably in board of the daggerboards.

Owen points out that this is different between IMOCA 60s and VO70s in that in light airs on the 60s when they sheet on the genoa the daggerboard can be raised, whereas on VO70s it can’t. “On VO70s, they sheet on the genoa and the daggerboard is always down, because the VO70s can’t develop enough side force with the keel alone, because of their righting moment, so the daggerboard is always out of the way. But on an Open 60 the daggerboard has the potential to get in the way, so it does affect some of the choices you make with the daggerboard geometry. So some boats are making these choices for different reasons.”

In addition to studying the different styles of daggerboard in the Madrid tank they also looked at the relationship between the daggerboards and the canted keel, upwind and downwind, when the daggerboards should be raised and the optimum angle between the daggerboards and keel.

“Some of this was done at very high speed as well, which was important from the hull trim side,” says Owen.

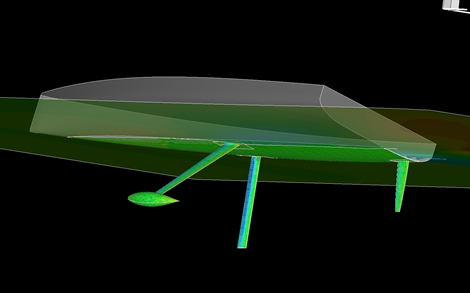

They also allocated a portion of this tank test time to some left field projects, on this occasion T-foil rudders (see photo below). “Because interceptors were banned, I wanted to see if we could use T-foil rudders as a trim control device for the bow, which is essentially a good part of what an interceptor does. It was pretty good, but they were too draggy in the end.”

Similarly when they did the tank testing for Ecover 3 they had looked at the possibility of lifting the whole boat out of the water on foils. “It was highly unlikely to have worked, but we learned a lot. The reason to do these things is to make sure you aren’t missing a trick. You don’t want to spent 4-5 million on a campaign in a couple of years and turn up with a boat, and find that someone has done a boat with a bow like David Raison’s Mini and blows you out of the water.”

So would the scow bow work on an IMOCA 60? “Clay brought it up as a hypothesis way back in the Ecover 3 days, because Team New Zealand had looked at it for the Cup. But the thing about David Raison’s project was that it took him a while to get it sorted and most 60 teams don’t have that much patience!

“In Class 40s it could work potentially, because Class 40s don’t have a measured righting moment limit. It has a stability limit, but that is only measured at 90 degrees not at a sailing angle like 20-30°. I very much doubt it would work on IMOCA 60s because there is a righting moment limit of 32 tonne metres now and the hull form is part of that measurement process because it is measured using the stability curves. So you are not getting righting moment for free like you are with the Mini.” However Owen also thinks the scow bow might work on VO70s. “I looked in the rule to see if there was a hull limit where there was a measure point and there is a 7/8th forward measure point and there is a height limit on it, but not a width limit. So I don’t see there being a reason why you couldn’t try it.”

Water ballast

Another area where VO70s and IMOCA 60s differ is that the latter are able to carry a substantial amount of water ballast and in recent design this has been shared between tanks forward, midships and aft (whereas the VO70s can only allowed to carry 1.6 tonnes in an aft tank).

“With Ecover 3, she was unique in that she had the same righting moment upwind as downwind,” says Owen, “which meant that when the rig was designed we weren’t adding extra weight to prevent it falling down when you went upwind. Typically boats before that would have a percentage higher righting moment upwind than downwind or reaching.”

Under the new IMOCA 60 rule there is a righting moment limit of 32 tonne metres. Owen points out that some of the light 60s (ie the VPLP Verdier designs) don’t even reach 30 tonne metres of righting moment. “We made the choice early on that the boat would be 32 tonne metres, and we have used every scrap of that. So that begs the question - where do you spend that righting moment? So we used Router for base modelling and we race modelled a number of the different ballast configurations using the optimum hull and we decided to spend our righting moment account in the reaching and downwind mode, but the way the rule now works is that it looks like you can’t quite get all that righting moment into the boat and pass AVS just with aft and reaching ballast. So you have to have some forward ballast. But in fact we were able to do that.”

So Acciona has no forward ballast tank (another weight saving). “The reality is that forward water ballast is being used less and less used by the 60s anyway. Once upon a time we used to go upwind at 9.5/9.6 knots and point. Then with Ecover 3 we were doing 10.3 and cracked. Quite often now the boats are doing 10.5 knots, even more cracked. Once you get to a certain point you are dumping that front ballast out of the boat and you are only using your reaching ballast. So that narrow angle where you used to be using that forward ballast got even narrower and in any case you were never putting in forward ballast until you got to 14 knots of wind anyway.”

Their studies also proved that the water ballast also has a significantly greater effect on the boat’s performance reaching and running and for a longer time, than it did upwind.

Keel stepped mast

In our article on Acciona, we pointed out the benefits of her keel stepped mast. Deck stepped masts were a feature of shorthanded boats that designers Finot-Conq came up with in the early 1990s where the idea was that in addition to maintaining the integrity of the hull in the event of a dismasting, structurally it enabled the mast to be sat on the main bulkhead (albeit with reinforcements).

As mentioned Acciona’s mast in fact is stepped on a box as it is on the Owen Clarke Class 40s 40 Degrees and Cinnamon Girl/mare.de. Owen explains why this is: “The compressions in the rig are quite big and it is the same on the 40 – so you need a pretty substantial girder in there. We are using a girder that forms the forward tank sides. If you put it too low down in the boat, then the structure becomes heavy because girder depth is quite small. If the girder is say 750mm deep, then it can be quite a light structure. The mast compression is typically 16-20 tonnes of pre-compression. As it happens, the thing sits at the same height as the water ballast tanks, which is the same height at the keel lid and we drain the bottom of the rig straight into the keel box. So we don’t get any water in the boat.”

Owen also points that these days it is extremely rare for a keel-stepped mast to break between the hull and deck, so keel-stepping the mast is no longer a safety issue.

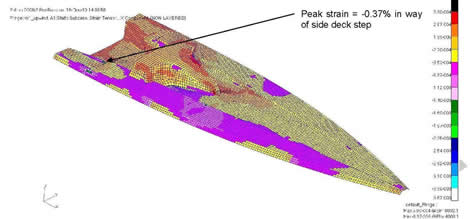

Strain model

Number crunching

For Acciona, the engineering of the boats main structure was carried out by SP Gurit who carried out a complete Finite Element Analysis of the hull. Like the tank test budget, Owen says that their engineering budget was substantially more than they have had available for past projects. SP Gurit carried out a specific analysis of the keel and ram area.

“For the first time we have changed how we’ve done that – again this was a function of the IMOCA rule change [ie to save weight]. In the past we had a very reliable system, with the steel pivot plates in the bottom of the boat, bolted into a carbon structure. This time around we were after every kilos we could get, so we managed to lose 60kg in the keel structure by designing a new way of doing it that is all in carbon.”

Pounds

In terms of displacement Acciona weighs in at 8.06 tonnes. While there were aspects such as her electric engine that were lighter than the equivalent diesel engine, with the added weight of extra batteries and her huge area of solar panels, overall going ‘Eco’ proved to be slightly heavier. However Owen points out that the boat is heavier in measurement trim and come the Vendee Globe race start she won’t be.

“We could get the boat more than 200kg lighter than that, but the reality that weight is in the boat in the form of batteries, so its effect on boat performance is pretty small. It is not like it is in the rig or deck - it is in the middle of the boat, wrapped around the keel area, and it is in the form of batteries. And if you think about what the boat weighs once you load kit on it and say you have half of your ballast in in a certain condition then that extra weight in the middle of the boat is neither here nor there. The VPP can’t even see it. So it is a no compromise race boat that just happens to be able to race with zero emissions."

Latest Comments

Mats Ohlsson 05/02/2012 - 09:25

Great article! I really love to drill down into technicalities. It is so interesting.381394 03/02/2012 - 12:01

What a brilliant article James. I've got a lot of time for Merfyn, and now it's reinforced by his frank and honest take on curved daggerboards. Following a trend for the sake of it is the easy way out, so hats off to him for sticking to what he believes is correct. Great looking boat guys!381394 03/02/2012 - 12:01

What a brilliant article James. I've got a lot of time for Merfyn, and now it's reinforced by his frank and honest take on curved daggerboards. Following a trend for the sake of it is the easy way out, so hats off to him for sticking to what he believes is correct. Great looking boat guys!Add a comment - Members log in